Research Focus at High Voltage Engineering and Asset Management

Schering-Institut

Asset Management

©

Schering-Institut/LUH

©

Schering-Institut/LUH

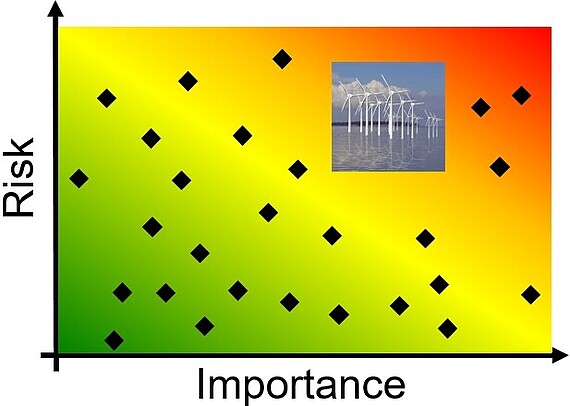

As a result of the liberalization of the electrical energy supply, the need for and interest in measures to increase reliability, optimized maintenance and extended service life of operating equipment (assets) have increased significantly in recent years. For this purpose, reliability and maintenance models of electrical equipment and networks are of particular importance. Based on the data collected by condition monitoring, an AI (artificial intelligence) system should evaluate the actual condition of the asset and provide information on what the risk of failure is, e.g., as a result of detected faults within the components or due to aging caused by electrical, thermal and mechanical stresses. Taking various models into account, all maintenance measures can then be optimized to minimize the risk of failure and thus maximize operational reliability. The research work in progress at the Schering Institute is concerned with the development of the fundamentals necessary for such asset management (AM) and the optimization of AM strategies with the aid of mathematical models.

Monitoring

©

Schering-Institut/LUH

©

Schering-Institut/LUH

The monitoring and status detection of electrical equipment (monitoring and diagnosis) is becoming increasingly important, as monitoring and diagnosis can increase the operational reliability of high-voltage components. The requirements for real-time detection systems are detection of relevant parameters, high reliability, long lifetime and use under operating conditions. The current investigations focus on the equipment plastic-insulated high-voltage cables, liquid-filled or solid-insulated high-voltage transformers and high-voltage machines. Modules are to be developed to build a modular, adaptive system that can be used for different components. The development of electronics and data processing algorithms as well as diagnostic procedures, based on the on-line acquired data, are research tasks which are worked on in this area together with industry and students.

Solid Insulating Materials

©

Schering-Institut/LUH

©

Schering-Institut/LUH

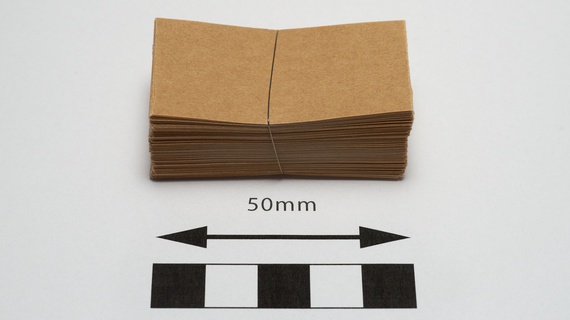

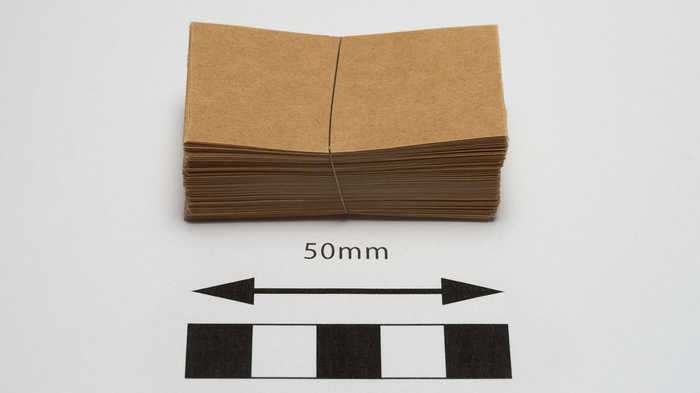

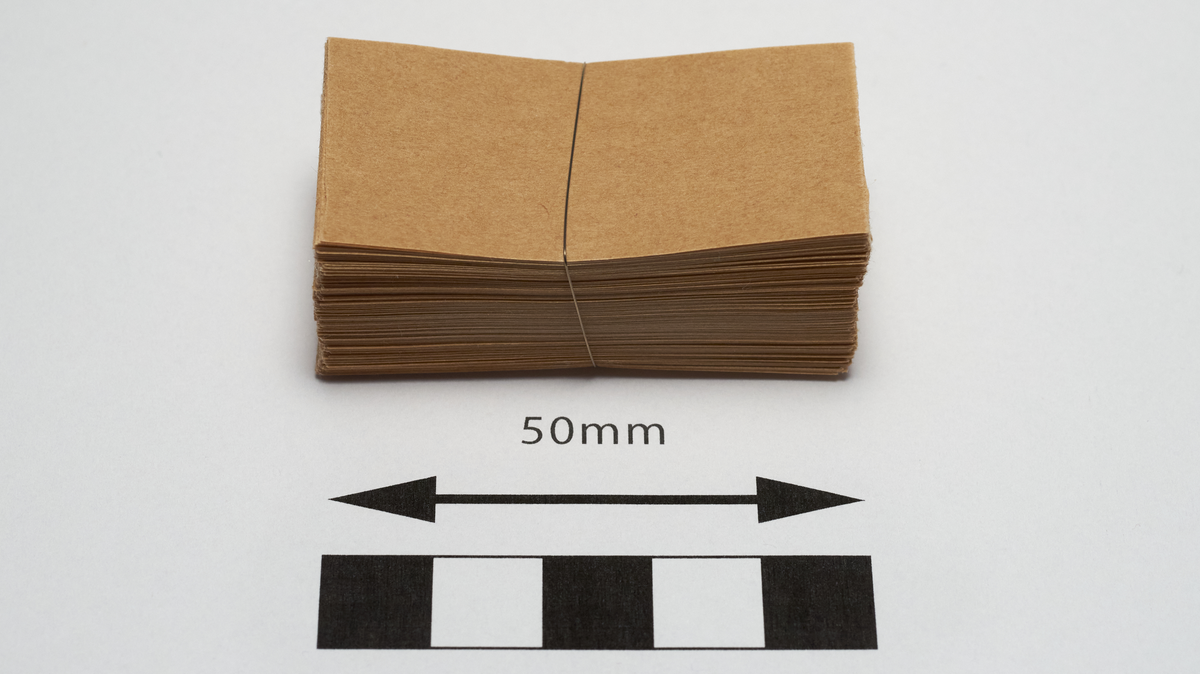

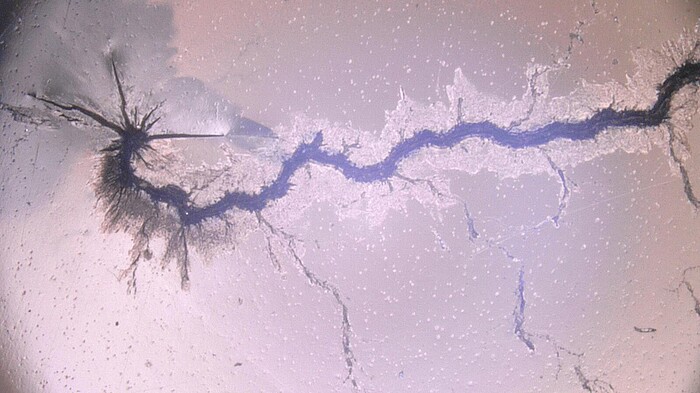

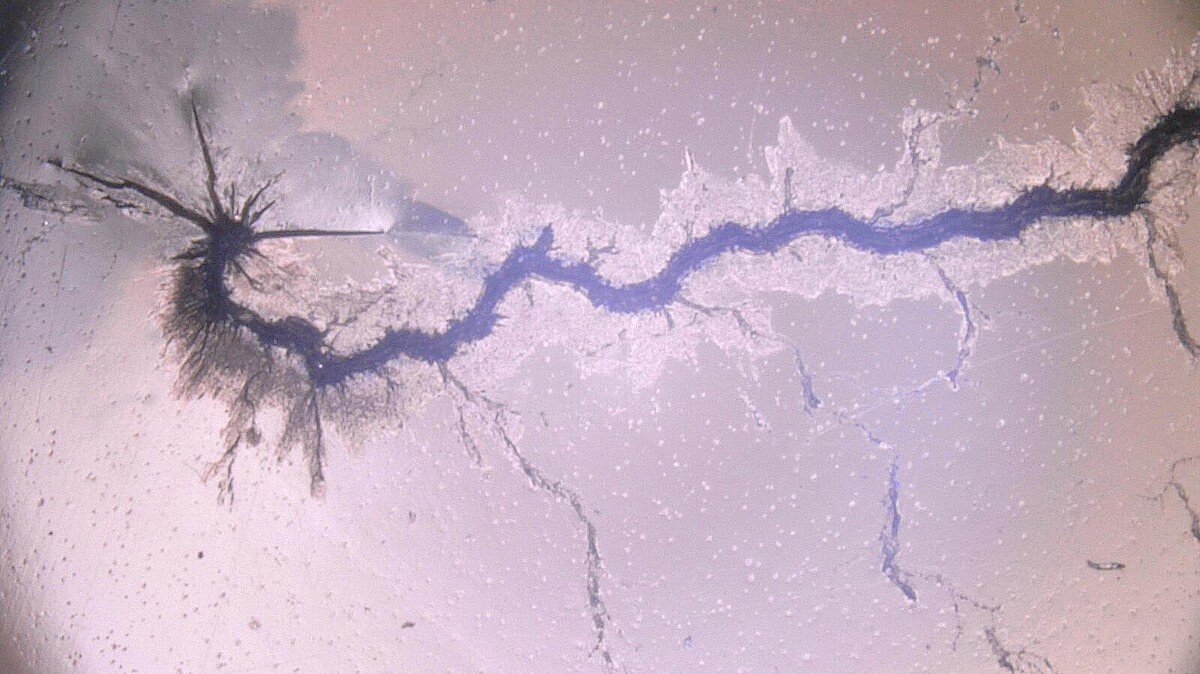

Solid insulating materials for medium- and high voltage applications as well as in the field of electromobility are permanently optimized, adapted and newly developed, as the requirements on the materials are continuously changing. Investigations at the Schering Institute focus on paper, polymers, elastomers, thermosets and reactive resin molding materials, modified with nanoparticles if necessary. The aging and durability determination of these solids as a function of thermal cycling and various mechanical and electrical stresses are being investigated to improve the reliability and longevity of the insulating materials. Voltage stresses are distinguished between impulse stress, high frequency impulse stress, AC and DC stress, and combined voltage stress, although extensive basic research is still needed to determine the influence of specific voltage stresses. In addition to voltage stresses, partial discharge measurements and the recording of dielectric parameters are also used to assess the quality of these insulating materials. New diagnostic methods are constantly being developed to enable the continuous recording of relevant data, which should lead to an improvement in the assessment and service life estimation.

Liquid Insulating Materials

©

Schering-Institut/LUH

©

Schering-Institut/LUH

Liquid insulating materials represent a special field of research at the Schering Institute, which is also reflected in the extensive equipment in the institute's own insulating liquid laboratory. The Schering Institute has been and continues to be extensively involved in the development of new insulating fluids for the high-voltage range and is developing and investigating fluids of the next but one generation, which can exhibit a wide range of optimized properties through modification with nanoparticles. Furthermore, aging behavior and the influence of various parameters on the physico-chemical properties of insulating fluids as well as the gassing behavior of the fluids are investigated, so that based on new findings and decades of experience, new methods of diagnosis and higher-level condition analysis are under development. The behavior of mixed fluids is also taken into account, as is the treatment and reuse of used insulating fluids.

Partial Discharge Technology Measurement

©

Schering-Institut/LUH

©

Schering-Institut/LUH

Partial discharge measurement is of particular importance in high-voltage technology, as this method can be used to detect the smallest weak points in the insulation of high-voltage components. Research in this area continues to focus on new methods of detection, the evaluation of partial discharge signals and, in particular, the location of the partial discharge source, whereby extensive basic research is still necessary for partial discharge measurement technology under DC voltage stress, which must then also be incorporated into corresponding standards. The Schering-Institute is researching these topics intensively in close cooperation with industry and other colleges and universities. In addition to these classic areas, partial discharge diagnostics is also becoming increasingly important in the field of electromobility, so that here, too, investigations and developments are increasingly taking place in cooperation with automobile manufacturers.

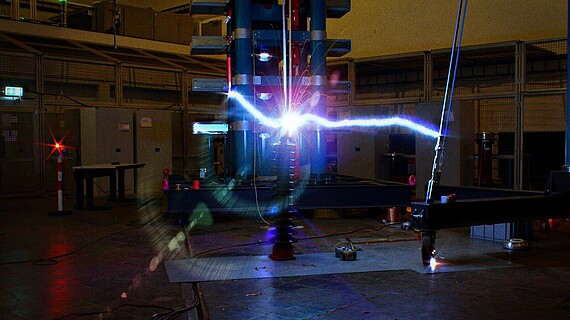

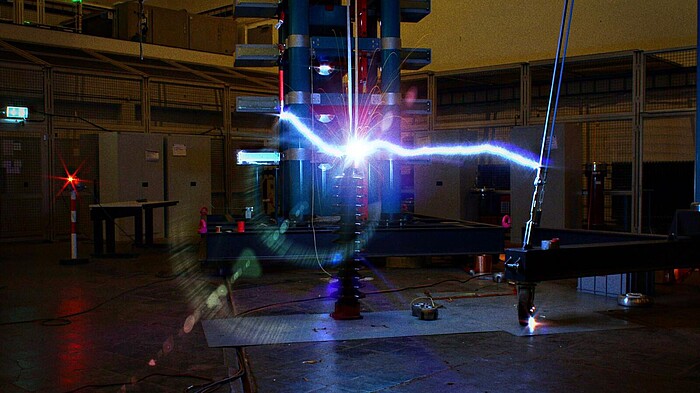

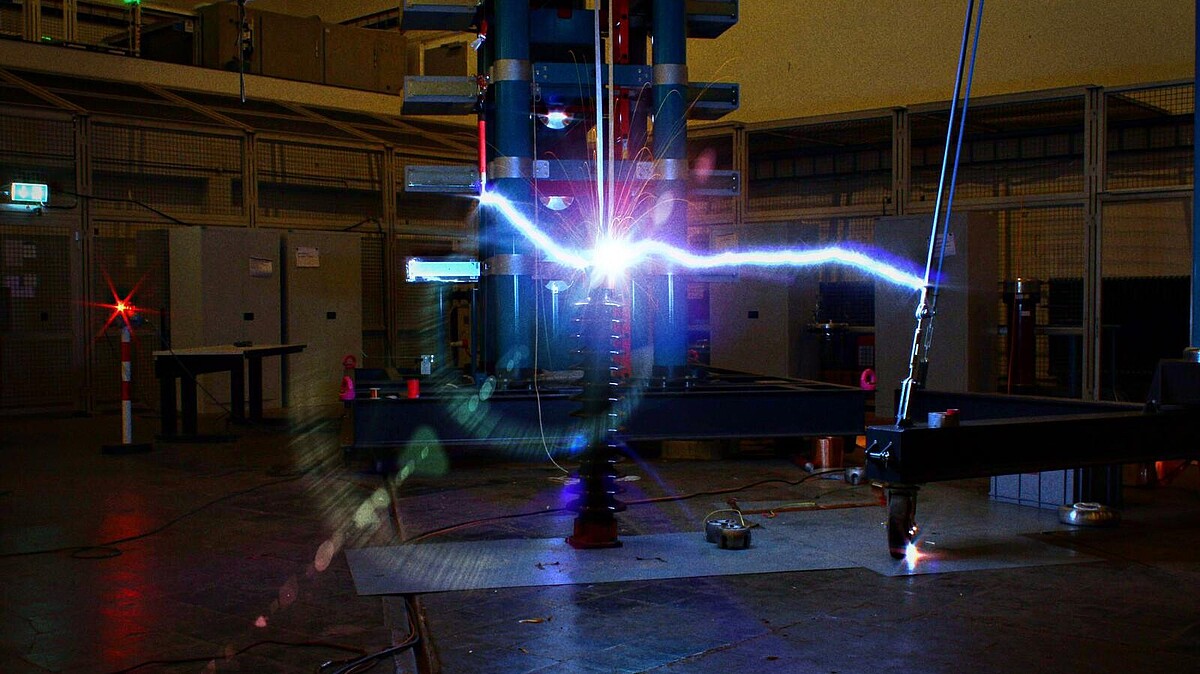

High Voltage Testing

©

Schering-Institut/LUH

©

Schering-Institut/LUH

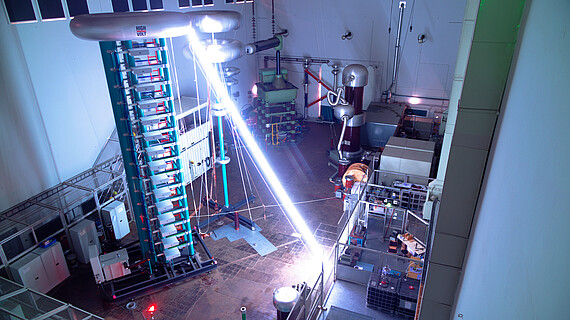

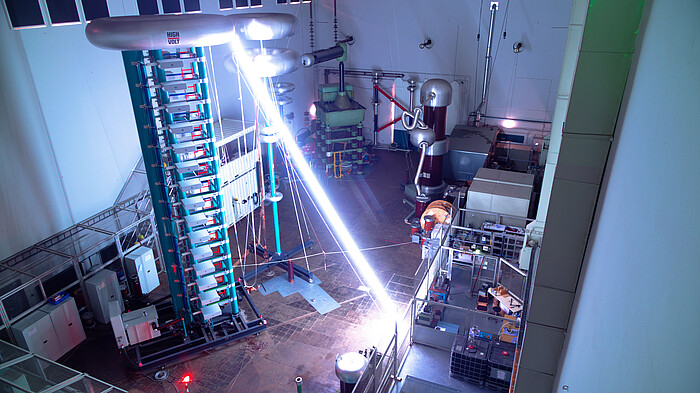

Within the framework of high voltage testing technology, research is being conducted into methods and devices for measuring and evaluating high voltages and currents. So called combined voltage stresses are increasingly used, which represent, for example, a superposition of DC and AC voltage, surge and DC voltage or surge and AC voltage. In order to describe these forms of stress, corresponding parameters of the voltage and/or current curve must be identified, which then enable an unambiguous representation. This form of representation can then be adopted in standards, ensuring that similar voltage or current waveforms are used as stresses for the components under test when testing in a wide variety of high-voltage test fields around the world. Furthermore, more compact and more powerful electronics allow new possibilities in the field of measurement technology, whereby it must be verified whether this can also be used reliably in the field of high electric and magnetic fields.

Electromagnetic Compatibility and Lightning Protection

©

Schering-Institut/LUH

©

Schering-Institut/LUH

In these fields of work, investigations are carried out on lightning protection systems with regard to current carrying capacity and current distribution. In particular, the interaction of metallic components and carbon fiber composites has been investigated for many years. Furthermore, the effects of lightning discharges on lines are analyzed as a function of their structure, location and coupling paths, and simulations of direct and indirect effects of a lightning discharge are carried out on components and model arrangements. A sensitive video system can also be used to detect sparks inside a model arrangement, allowing an evaluation of the various connecting elements in terms of their current carrying capacity and spark generation. The results can be used to improve lightning protection measures and to modify recommendations of lightning protection measures for future designs.

Electromobility

©

Bild von A. Krebs auf Pixabay

©

Bild von A. Krebs auf Pixabay

In the field of electromobility, increasingly stringent requirements are being placed on electric motors and converters. Therefore, material compatibility tests and aging simulations for newly developed insulating and cooling media are carried out. In addition, based on many years of experience in the field of diagnosis of large machines, new testing and diagnostic methods for electric drives are being sought. In this research area there is a close cooperation with the Institute for Drive Systems and Power Electronics (IAL).

Contact

30167 Hannover